Liste des articles janvier – février 2025

Experimental investigation on dynamic stab resistance of high-performance multi-layer textile materials

Mulat Alubel Abtew (a), François Boussu(b), Irina Cristian (c), Bekinew Kitaw Dejene (d)

Show more

- a University of Missouri, College of Arts and Science, Department of Textile and Apparel Management, Columbia 65211, USA

- b Lille Université, ENSAIT, GEMTEX lab., 2 All. Louise et Victor Champier, Roubaix 59056, France

- c Gheorghe Asachi Technical University of Iasi, Faculty of Industrial Design and Business Management, Iași 700050, Romania

- d Hawassa University, Dept. of Textile Engineering, Institute of Technology, Hawassa, Ethiopia

Abstract

Stab-resistant textiles play a critical role in personal protection, necessitating a deeper understanding of how structural and layering factors influence their performance. The current study experimentally examines the effects of textile structure, layering, and ply orientation on the stab resistance of multi-layer textiles. Three 3D warp interlock (3DWI) structures ({f1}, {f2}, {f3}) and a 2D woven fabric ({f4}), all made of high-performance p-aramid yarns, were engineered and manufactured. Multi-layer specimens were prepared and subjected to drop-weight stabbing tests following HOSBD standards. Stabbing performance metrics, including Depth of Trauma (DoT), Depth of Penetration (DoP), and trauma deformation (Ymax, Xmax), were investigated and analyzed. Statistical analyses (Two- and One-Way ANOVA) indicated that fabric type and layer number significantly impacted DoP (P < 0.05), while ply orientation significantly affected DoP (P < 0.05) but not DoT (P > 0.05). Further detailed analysis revealed that 2D woven fabrics exhibited greater trauma deformation than 3D WIF structures. Increasing the number of layers reduced both DoP and DoT across all fabric structures, with f3 demonstrating the best performance in multi-layer configurations. Aligned ply orientations also enhanced stab resistance, underscoring the importance of alignment in dissipating impact energy.

Under a Creative Commons license

Durable Textile Dyeing/Printing Using Natural Indigo Dyes and Leaves, and Mayan-Inspired Blue Indigo Pigments. Colorants, 4(1).

Behary, N., & Volle, N.

Show more

- 1 ENSAIT-GEMTEX, 59100 Roubaix, France2 ULR 2461, Textile Research Laboratory (GEMTEX), University Lille, 59000 Lille, France3 PIGM’Azur—Products For Innovative Green Materials, 99 Route de Canta Galet, 06200 Nice, France*Author to whom correspondence should be addressed.

Abstract

Indigo leaves from various plant species are sources of dyes/pigments, not fully exploited for making sustainable textiles. Blue indigo vat dye extracted from indigo leaves yields high wash color fastness but fades slowly with light, and is not easily used for direct printing. Indigo leaves can be used to produce textiles of various color shades, while light-resistant Mayan-inspired hybrid pigments have not yet been used for textile coloring. Using blue indigo dyes from three plant species, with exhaustion dyeing, intense wash-resistant blue-colored textiles are produced, and in the case of Indigofera Persicaria tinctoria, textiles have antibacterial activity against S. epidermis and E. coli. A 100% natural Mayan-inspired blue indigo pigment, made from sepiolite clay and natural indigo dye, was used both in powdered and paste forms to perform pigment textile dyeing by pad cure process, and direct screen printing on textiles. A water-based bio-binder was used efficiently for both padding and printing. Bio-based Na Alginate thickener allowed to produce prints with good color-fastness on both polyester and cotton fabrics, while bio-based glycerin produced excellent print color fastness on polyester only: wash fastness (5/5), dry and wet rub fastness (5/5) and light fastness (7/8).

Under a Creative Commons license

Reliability modeling of tensile properties in recycled carbon fibers: A comparative fit of statistical distributions pre- and post-textile processing

Jean Ivars, Kim Phuc Tran, Ahmad Rashed Labanieh, Damien Soulat

Show more

- Univ. Lille, ENSAIT, ULR 2461 – GEMTEX – Génie et Matériaux Textiles, Lille F-59000, France

Received 21 November 2024, Revised 9 January 2025, Accepted 2 February 2025, Available online 4 February 2025, Version of Record 8 February 2025.

Abstract

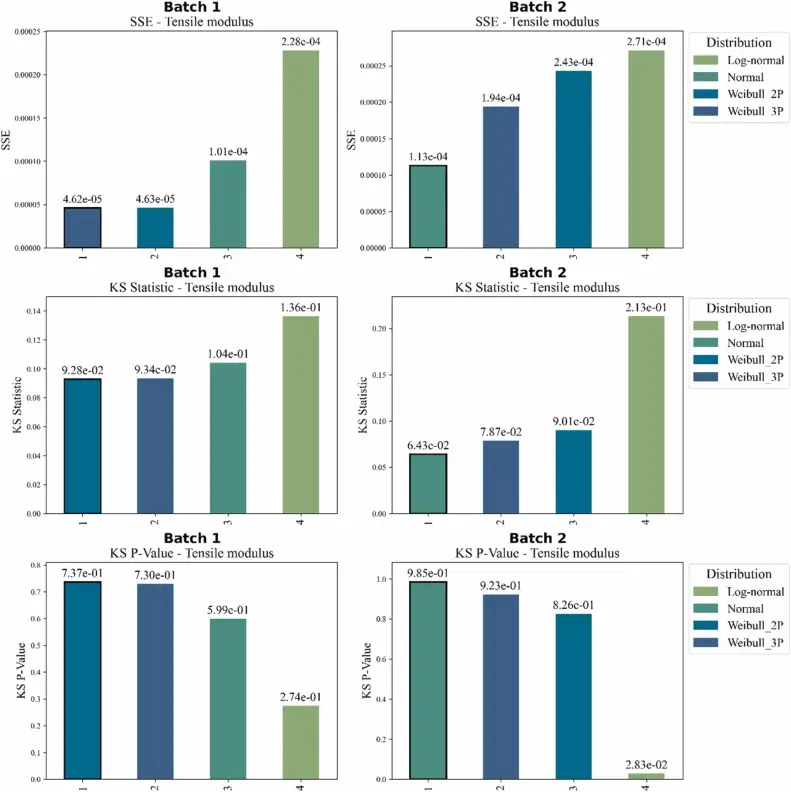

Due to their extensive use in the aerospace, automotive, wind energy, and sports industries, the recycling of carbon fiber composites has become increasingly important. Characterization of the tensile properties of these recycled fibers is essential, using single fiber tensile tests that provide data on tensile strength, elongation at break, and tensile modulus. This study compares four statistical distributions—2-parameter Weibull, 3-parameter Weibull, Normal, and Lognormal—to fit tensile data from two batches of recycled carbon fibers: one after recycling, and the same type of fiber after a further carding process. Maximum Likelihood Estimation (MLE) was used for the fitting process, while the Sum of Squared Errors (SSE) and Kolmogorov-Smirnov (KS) tests were employed to evaluate the fitting performance. The 2-parameter Weibull distribution provided the best fit overall for tensile strength, elongation at break, and tensile modulus. However, the Normal distribution performed slightly better for tensile strength and tensile modulus in the post-carding batch, indicating that different models might be more appropriate at various processing stages. This study illustrates the challenge of selecting a single model and balancing computational accuracy with mechanical consistency across different properties and conditions, providing insights into the complex behavior of discontinuous fiber composites and contributing to a better understanding of the mechanical challenges associated with recycled materials and their processing.

Under a Creative Commons license

Influence of the Thermoplastic Fiber Ratio on the Mechanical Properties of Recycled Carbon Fibers During the Carding Process

by Jean Ivars, Ahmad Rashed Labanieh and Damien Soulat *

Show more

ULR 2461-GEMTEX-Génie et Matériaux Textiles-Gemtex, Ensait, University of Lille, F-59000 Lille, France

* Author to whom correspondence should be addressed.

Abstract

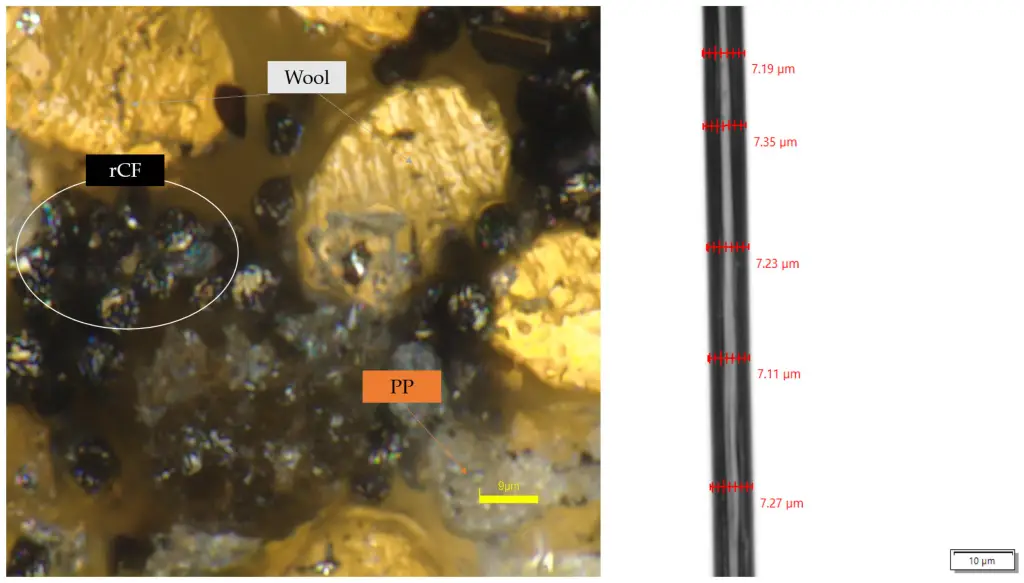

This study investigates the impact of carding and blending recycled carbon fibers (rCF) with crimped thermoplastic polypropylene (PP) fibers on the mechanical properties of rCF, using a Weibull statistical approach. Tensile properties of rCF were evaluated before and after carding with varying rCF/PP blend ratios (100/0%, 85/15%, 70/30%, and 50/50%). A comparison between the two-parameter and three-parameter Weibull models showed that the two-parameter model provided a better fit for rCF properties before carding. The results show that adding crimped PP fibers during carding helps to decrease the stress-at-break disparity and move their distribution to higher values. Furthermore, a slight increase in tensile modulus was observed in carded rCF, with higher PP ratios associated with smaller scatter modulus distributions. Elongation at break remained consistent, with the Weibull modulus increasing slightly with carding and the inclusion of PP fibers, indicating improved consistency. Overall, carding rCF with PP fibers helped in the mechanical property uniformity of the resulting carded webs without compromising tensile performance. This work shows the potential of the carding process with or without thermoplastic fibers to efficiently realign and give continuity to discontinuous recycled carbon fibers.

Under a Creative Commons license

SVDD control charts based on MEWMA technique for monitoring compositional data

Thi Thuy Van Nguyen (a b), Cédric Heuchenne (a), Kim Duc Tran (c b), Guillaume Tartare( b), Kim Phuc Tran (b)

Show more

- a HEC Liège – Management School, University of Liège, 4000, Liège, Belgium

- b ENSAIT, ULR 2461 – GEMTEX – Génie et Matériaux Textiles, Univ. Lille, F-59000, Lille, France

- c IAD, Dong A University, 50000, Da Nang, Viet Nam

Received 6 May 2024, Revised 2 January 2025, Accepted 4 January 2025, Available online 11 January 2025, Version of Record 16 January 2025.

Abstract

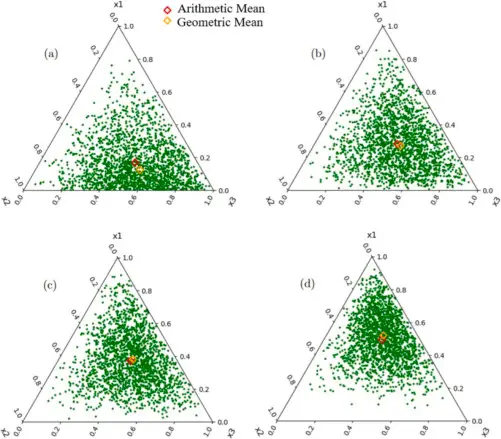

Monitoring compositional data (CoDa) using control charts has become increasingly important in Statistical Process Control (SPC). This study introduces two approaches for CoDa monitoring, utilizing support vector data description (SVDD) control charts in conjunction with the multivariate exponentially weighted moving average (MEWMA) technique, specifically focusing on Phase II monitoring processes. The proposed approaches use two transformation methods: the Dirichlet density transformation and the isometric log-ratio transformation. We evaluate the effectiveness of the proposed SVDD control charts by computing the out-of-control zero-state Average Run Length () using simulated data. Our results demonstrate that SVDD control charts detect anomalies more effectively than the traditional MEWMA control chart across various scenarios in monitoring CoDa. These findings contribute to the advancement of SPC and offer valuable insights for practitioners involved in CoDa monitoring across diverse applications.

Under a Creative Commons license

A new omnibus SPRT chart for monitoring process mean and variability based on the average number of observations to signal

J.W. Teoh, W.L. Teoh, XueLong Hu, K.P. Tran, & D.G. Godase

Show more

Pages 49-69 | Received 08 Mar 2024, Accepted 10 Oct 2024, Published online: 18 Oct 2024

Abstract

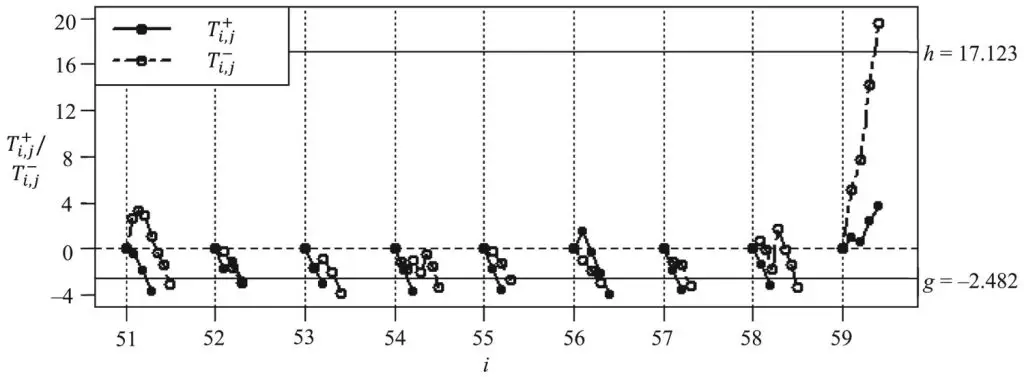

The recent development of the omnibus sequential probability ratio test (OSPRT) chart marks a significant contribution to the advancement of joint monitoring schemes. As the OSPRT chart is a variable-sample-size control chart, practitioners often wish to understand its inspection efficiency, i.e. the number of observations it samples before producing a signal. In this article, we propose two enhanced optimization designs for the OSPRT chart based on the average number of observations of signal (ANOS) and expected value of the ANOS (EANOS) metrics under deterministic and unknown shift sizes, respectively. The ANOS metric is central to our design as it perfectly combines both the average run length (ARL) and the average sample number. A comparative analysis reveals that the OSPRT chart outperforms four benchmarking control charts in terms of the ANOS and EANOS metrics. Finally, an implementation of the OSPRT chart is presented with a ball shear test dataset.

Under a Creative Commons license

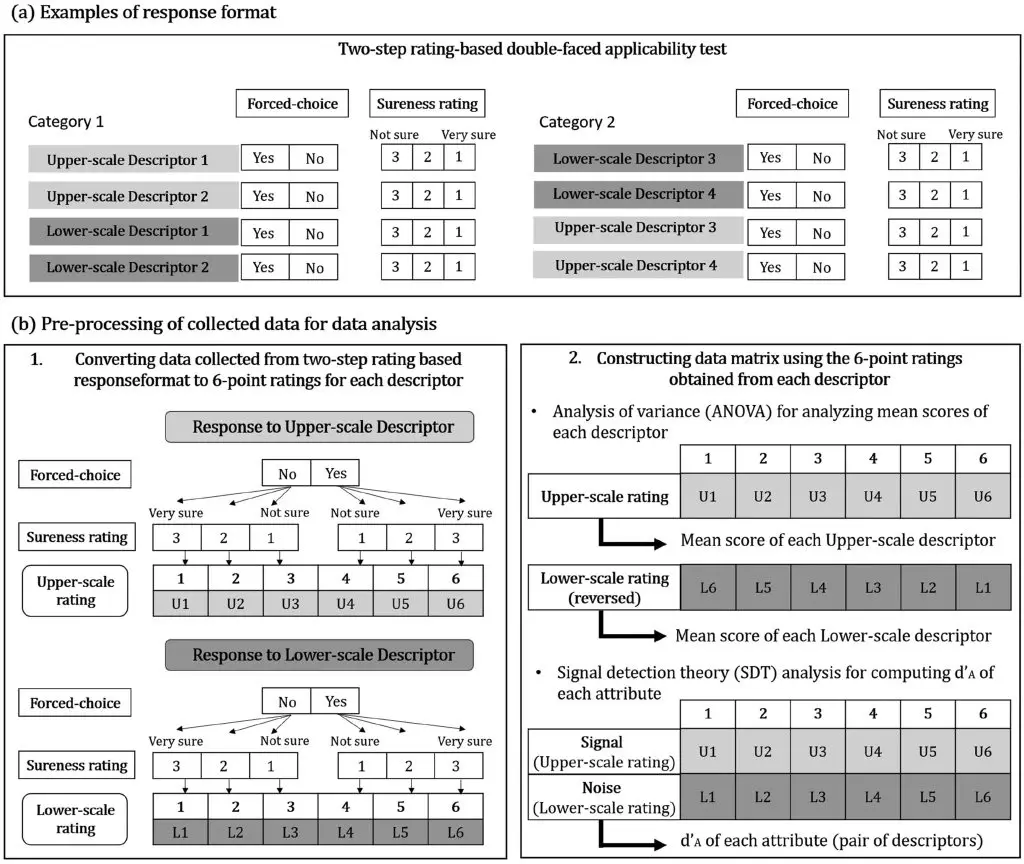

Investigating the effects of cognitive scenarios between real fabric and fabric visual representations

Bo Xing, Qingqing Shao, Xianyi Zeng, Ludovic Koehl, and Jun Wang

Show more

Abstract

The present study delves into the cognitive aspects of fabric hand evaluation, particularly under varying scenarios of real touch and visual representations (image, video). Conducted within a cognitive psychology framework, the study used a two-step rating-based double-faced applicability (DFA) test across a panel of 30 experts who evaluated 101 textile samples using 20 semantic differential descriptors. The findings indicate scenario-based discrepancies, especially pronounced within the thermal-wet sensation properties, underscoring the difference between real touch and visual representations on sensory ratings. By implementing the DFA test, the research reveals biases inherent in fabric hand evaluations and suggests modifications to enhance validity. This work not only contributes to textile quality assessment methods by recognizing scenario effects but also advances the understanding of the cognitive processing behind textile sensory perception.

Under a Creative Commons license

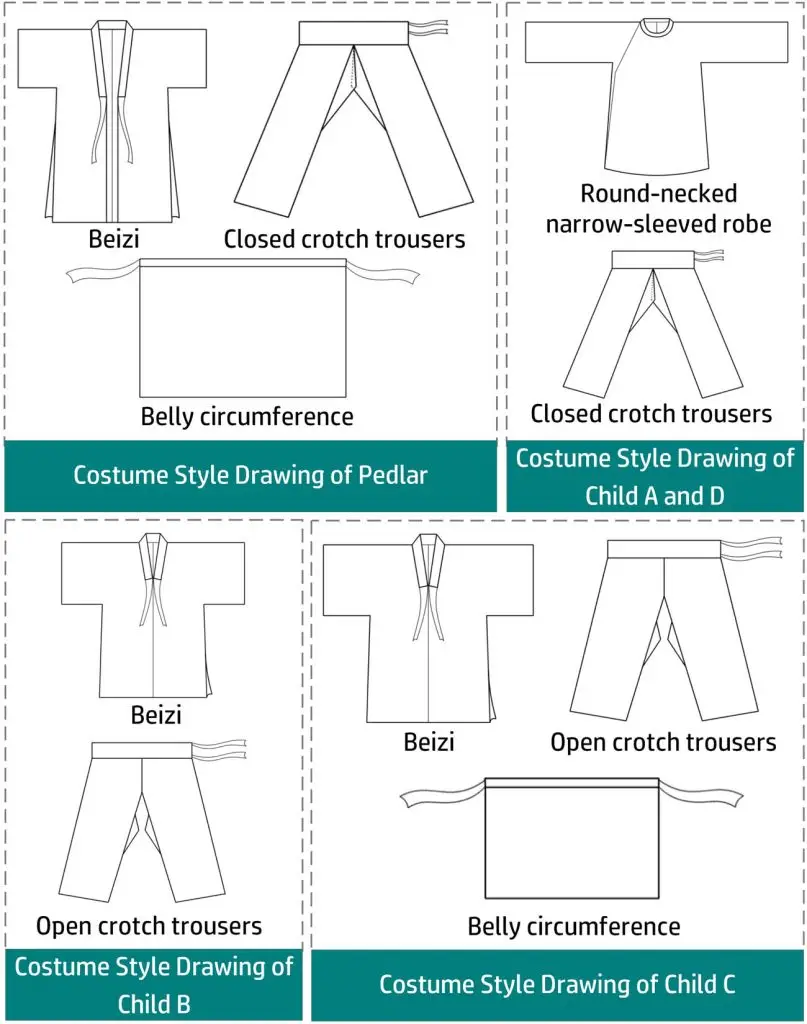

Study and restoration of the costume of the HuoLang (Peddler) in the Ming Dynasty of China

C. Zhu (1) , Y. Y. Gao (2) , J. P. Wang (1) , Xianyi Zeng (3) , Pascal Bruniaux (3) , K. X. Liu (2, 3)

Show more

2 Xi’an Polytechnic University

3 GEMTEX – Génie des Matériaux Textiles – ULR 2461

Abstract

This study looks at two aspects of ancient Chinese genre painting to interpret the more realistic ancient shopping scenes in the painting of the peddler in spring scenery in the Ming Dynasty, namely, the Ming spring scene and the characters’ costume image features. Through the analysis of the detailed characteristics of the style, structure, pattern, and color of the figure costume in the painting of the peddler, a total of five sets of figure costume for an adult male and four children in the painting of the peddler in the spring scenery of the Ming Dynasty in China were digitally restored using the 3D virtual fitting technology, which clearly showed the characteristics of the figure costume of the peddler and children in the Ming Dynasty (1368–1644). The figure’s costume style in the painting of the salesman restored in the article is Beizi, closed crotch trousers, open crotch trousers, and abdominal circumference (a type of apron from the Song Dynasty. It is made to resemble a short apron and is wrapped around the abdomen). The study of the painting of peddler in the Ming dynasty in this work provides a reference for future study on ancient Chinese genre paintings of peddler and the restoration of the costumes of the figures in the painting.

Under a Creative Commons license

Liste chapitre de livres janvier-février 2025

Deformability and preforming characterization of nonwoven fabrics

Ahmad Rashed Labanieh 1, Damien Soulat 1, Fatma Omrani 2

Show more

- 1 Univ. Lille, ENSAIT, Laboratoire Génie et Matériaux Textiles (GEMTEX), Lille, France

- 2 AMRC, University of Sheffield, United Kingdom

Available online 30 August 2024, Version of Record 30 August 2024.

Characterization, Modeling, and Simulation

Woodhead Publishing Series in Composites Science and Engineering

2025, Pages 145-162

Abstract

Nonwoven fabrics, known for their mechanical and acoustic properties, have gained attention in various industries, including automotive applications. The use of natural fibers or recycled carbon fibers (rCF) in nonwoven structures offers a cost-effective and sustainable solution. However, the deformability during tensile loads and/or during the forming process remains poorly understood. Compared to long-fiber fabrics, types of defects occurring during these solicitations (tensile/forming step) are few described in the literature. This chapter is not only based on previous studies but also contains new results. After the introduction, the first section is dedicated to the tensile behavior of these nonwoven fabrics at a dry scale, with a short state-of-the-art which is followed by some results of tensile tests performed on nonwoven made from rCF. The second part of this chapter is dedicated to the preforming of nonwoven fabrics where new types of defects, such as tears, are highlighted during this forming.